How Effective is PU Foam Exterior Wall Sandwich Panel for Heat Insulation?

2023/8/3

Introduction

In the pursuit of sustainable and energy-efficient construction materials, the use of insulated panels for building exteriors has gained significant popularity. Among these options, Polyurethane (PU) foam exterior wall sandwich panels have emerged as a promising choice for providing excellent heat insulation. In this article, we will explore the characteristics and advantages of PU foam exterior wall sandwich panels, analyzing their effectiveness in heat insulation.

What are PU Foam Exterior Wall Sandwich Panels?

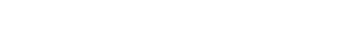

PU foam exterior wall sandwich panels consist of a core made of polyurethane foam sandwiched between two rigid facing materials, often metal sheets. The panels are manufactured through a specialized process that injects liquid polyurethane foam between the facing sheets, allowing it to expand and create a dense, closed-cell structure. This construction technique provides exceptional thermal insulation properties, making it an attractive option for building exteriors.

Superior Thermal Insulation

One of the key benefits of PU foam exterior wall sandwich panels is their remarkable thermal insulation capabilities. The closed-cell structure of the polyurethane foam effectively traps air within its pockets, significantly reducing heat transfer through conduction. As a result, the panels exhibit high thermal resistance (R-value), preventing heat from passing through the walls and minimizing the need for additional heating or cooling within the building.

Energy Efficiency

The superior thermal insulation of PU foam exterior wall sandwich panels translates into enhanced energy efficiency for buildings. By minimizing heat transfer across the walls, these panels can substantially reduce heating and cooling loads, leading to lower energy consumption and utility bills. Additionally, their lightweight nature allows for easier installation and reduced structural requirements, further contributing to overall energy savings.

Seamless Installation

PU foam exterior wall sandwich panels are known for their ease of installation. With their interlocking design and precise dimensions, they can be seamlessly joined together, forming a tight building envelope. This minimizes gaps and potential thermal bridges, ensuring a continuous barrier against heat transfer. The quick installation process also saves time and labor costs, making it an attractive option for both new construction and renovation projects.

Moisture and Fire Resistance

Beyond thermal insulation, PU foam exterior wall sandwich panels offer additional benefits. The closed-cell structure of the polyurethane foam resists moisture infiltration, preventing issues like condensation and mold growth. Moreover, these panels can be manufactured with fire-resistant properties, enhancing building safety and adhering to fire codes and regulations.

Longevity and Durability

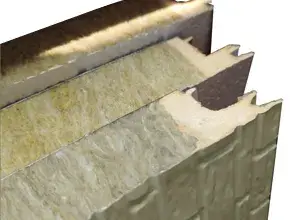

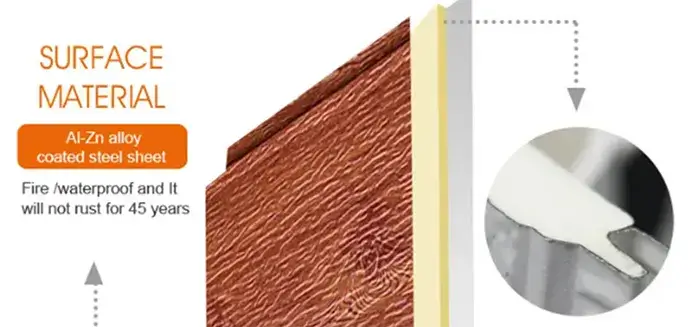

PU foam exterior wall sandwich panels are known for their durability and longevity. The rigid facing materials protect the polyurethane core from physical damage and UV exposure, ensuring the panels' integrity over time. Their robust construction allows them to withstand harsh environmental conditions, making them a suitable option for various climates.

Conclusion

PU foam exterior wall sandwich panels stand out as an exceptional choice for heat insulation in buildings. Their superior thermal insulation properties, energy efficiency, seamless installation process, and additional benefits such as moisture and fire resistance make them a compelling option for modern construction projects. As we continue to prioritize sustainability and energy conservation, PU foam exterior wall sandwich panels are likely to play a crucial role in shaping the buildings of the future. However, it's essential to consider specific project requirements and consult with experts to ensure the best results and optimal performance of these panels in any construction endeavor.

In the pursuit of sustainable and energy-efficient construction materials, the use of insulated panels for building exteriors has gained significant popularity. Among these options, Polyurethane (PU) foam exterior wall sandwich panels have emerged as a promising choice for providing excellent heat insulation. In this article, we will explore the characteristics and advantages of PU foam exterior wall sandwich panels, analyzing their effectiveness in heat insulation.

What are PU Foam Exterior Wall Sandwich Panels?

PU foam exterior wall sandwich panels consist of a core made of polyurethane foam sandwiched between two rigid facing materials, often metal sheets. The panels are manufactured through a specialized process that injects liquid polyurethane foam between the facing sheets, allowing it to expand and create a dense, closed-cell structure. This construction technique provides exceptional thermal insulation properties, making it an attractive option for building exteriors.

Superior Thermal Insulation

One of the key benefits of PU foam exterior wall sandwich panels is their remarkable thermal insulation capabilities. The closed-cell structure of the polyurethane foam effectively traps air within its pockets, significantly reducing heat transfer through conduction. As a result, the panels exhibit high thermal resistance (R-value), preventing heat from passing through the walls and minimizing the need for additional heating or cooling within the building.

Energy Efficiency

The superior thermal insulation of PU foam exterior wall sandwich panels translates into enhanced energy efficiency for buildings. By minimizing heat transfer across the walls, these panels can substantially reduce heating and cooling loads, leading to lower energy consumption and utility bills. Additionally, their lightweight nature allows for easier installation and reduced structural requirements, further contributing to overall energy savings.

Seamless Installation

PU foam exterior wall sandwich panels are known for their ease of installation. With their interlocking design and precise dimensions, they can be seamlessly joined together, forming a tight building envelope. This minimizes gaps and potential thermal bridges, ensuring a continuous barrier against heat transfer. The quick installation process also saves time and labor costs, making it an attractive option for both new construction and renovation projects.

Moisture and Fire Resistance

Beyond thermal insulation, PU foam exterior wall sandwich panels offer additional benefits. The closed-cell structure of the polyurethane foam resists moisture infiltration, preventing issues like condensation and mold growth. Moreover, these panels can be manufactured with fire-resistant properties, enhancing building safety and adhering to fire codes and regulations.

Longevity and Durability

PU foam exterior wall sandwich panels are known for their durability and longevity. The rigid facing materials protect the polyurethane core from physical damage and UV exposure, ensuring the panels' integrity over time. Their robust construction allows them to withstand harsh environmental conditions, making them a suitable option for various climates.

Conclusion

PU foam exterior wall sandwich panels stand out as an exceptional choice for heat insulation in buildings. Their superior thermal insulation properties, energy efficiency, seamless installation process, and additional benefits such as moisture and fire resistance make them a compelling option for modern construction projects. As we continue to prioritize sustainability and energy conservation, PU foam exterior wall sandwich panels are likely to play a crucial role in shaping the buildings of the future. However, it's essential to consider specific project requirements and consult with experts to ensure the best results and optimal performance of these panels in any construction endeavor.