Look Deep Into IND Facade Panels

2019/6/6

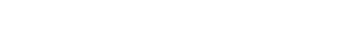

The panel has been called IND panel mostly because of its multi-functions of insulation and decoration. It’s a kind of polyurethane sandwich panel, but different from the traditional PU sandwich panel.

Structures of Two Popular Types of IND Panels

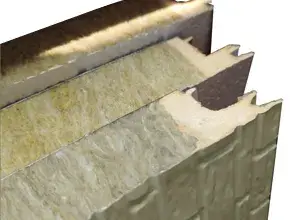

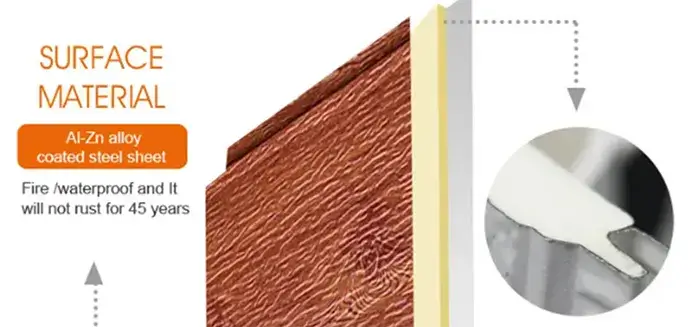

IND facade panel is quite lightweight, only max. 20mm thickness (standard thickness 16mm), and only 3.7kg per square meter. IND panel is made of surface layer, core layer and back layer. The surface layer is prepainted-aluzinc steel sheet, shaped either by roll forming or embossing or both to creat different 3D patterns for decoration purpose. The core material is high-density rigid PU foam to ensure about 10 centi-degrees difference between inside and outside of the building with IND facade panel. The back layer is waterproof aluminum foil, preventing wall against rainwater or moisture.

The IND panels perform wondefully as facade panels for a lot of buildings or applications, for example, municipal construction, residential apartments, villas, gardens, refurbishment of old buildings, guard posts, selling boxes and many other engineering fields etc.

IND Panel Joint Method

Features of IND Multi-functional wall panels:

Section Drawings of the IND Panels

According to World Steel Association, the durability of Al-zinc steel with 55% aluminium is 3-6 times longer that that of galvanized steel sheet and aluminium.

Structures of Two Popular Types of IND Panels

IND facade panel is quite lightweight, only max. 20mm thickness (standard thickness 16mm), and only 3.7kg per square meter. IND panel is made of surface layer, core layer and back layer. The surface layer is prepainted-aluzinc steel sheet, shaped either by roll forming or embossing or both to creat different 3D patterns for decoration purpose. The core material is high-density rigid PU foam to ensure about 10 centi-degrees difference between inside and outside of the building with IND facade panel. The back layer is waterproof aluminum foil, preventing wall against rainwater or moisture.

The IND panels perform wondefully as facade panels for a lot of buildings or applications, for example, municipal construction, residential apartments, villas, gardens, refurbishment of old buildings, guard posts, selling boxes and many other engineering fields etc.

IND Panel Joint Method

Features of IND Multi-functional wall panels:

- The middle material, high rigid pu core, can make very good heat insulation effect. The insulation efficiency is equal to 40 thickness EPS material and also good for noiseproof.

- The panel is light enough, and easy to be installed on the wall so that the installation time and cost can be minimized. At the same time because of this character, also be a anti-seismic building material.

- The surface of siding coated on Aluminum alloy steel with high weather-resistant agent, so it is excellent for waterproof and anti-condensation. And its lifetime can be longer more than 20 years.

- The panel surface is made in the compression method for better intaglio, therefore there are many different patterns are available. Customers have many choices.

Section Drawings of the IND Panels

According to World Steel Association, the durability of Al-zinc steel with 55% aluminium is 3-6 times longer that that of galvanized steel sheet and aluminium.

Advantages of the PU insulataion decorative metal siding panels:

- Higher Insulating values: The middle material is high rigid pu core, can get a very good heat insulation result. The insulation result is equal to 40 thickness EPS material. 10℃Warmer than house decorated with paint, 7℃ warmer than house decorated with PVC panels.

- Lower energy costs: It is a light material and very easy to be install on the wall, so can reduce the time and cost of installation. An experienced worker can install more than 100 square meters one day.

- Anti-seismic and Anti-cracking: This kind of panel is light weight building material, and therefore is anti-seismic building material.

- Superior durability: The surface of siding coated on Aluminum alloy steel with high weather-resistant agent, so it is excellent for waterproof and anti-condensation. And its lifetime can be longer more than 20 years.

- Beautiful Appearance: The panel surface is made in the compression method for better intaglio, therefore there are many different patterns are available. Customers have many choices.

- Waterproof and damp-proof: The panel is waterproof and damp-proof material, so there is no need to worry about the wall go moldy.

- Sound insulation and Noise reduction: The core material of the panel is high rigid polyurethane foam, 29DB noise can be prevented. The soundproof effect the same as solid wall Provide a quiet and comfortable environment even in noisy areas.

- Recyclable: The panel can be reused many times.

- High strength: Perfect combination of galvanized steel sheet with hard polyurethane foam allow panel resistant to pressure.

- Fireproof: The panel can reach B1 level.

- Harmless: The panel is eco-friendly building material, No formaldehyde, odorless and pollution-free and so on.